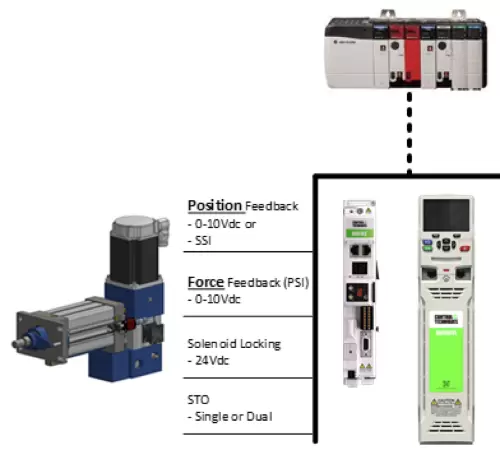

Total Solution Control Package - Hardware and Software Features

Our 'Total Solution' controls package includes an array of hardware options and comprehensive software capabilities that make it easy to implement various control modes, control processes with “pass/fail” determinations, log data for analysis and interface with common fieldbus options.

Kyntronics offers a variety of controls packaging options including backplates that mount in your enclosure, full enclosure options, and multiple axis versions. Best of all, with our “Total Solution” package, we assist with system tuning, factory testing of the complete system, and comprehensive remote support to help you commission your system efficiently and productively.

Total Solution – Control Hardware Features:

Single Drive on panel Backplate

Single Drive Enclosure

Multi-Axis on Panel / Backplate

Multi-Axis Enclosure

Three Selectable Modes (selectable at any time)

Position Mode

(can be used for a constant speed mode)Position with Force Limiting

(Bump-less switchingfrom Position to Force control)

Force Mode

Connectivity to most any PLC / Controller – e.g., ABB, Allen Bradley, Automation Direct, Delta Motion, Mitsubishi, Siemens, Yaskawa, etc.

Connectivity:

- CANopen

- Ethernet TCP/IP

- Ethernet IP

- EtherCAT

- Modbus TCP

- Modbus RTU

- Profinet

- Analog/Digital

- Other - Consult Factory

Servo Drives used with the Kyntronics Total Solution:

- Nidec / Control Techniques

- Unidrive, Digitax, M750, M700

- Uses the MCi200 & MCi210 programming modules integrating the Kyntronics standard software

Drive Interface:

- Analog & Digital

- Fieldbus

- STO

- Single or Dual

Digitax HD:

- 200 Vac | 400 Vac

- 24Vdc to 800Vdc (for Battery / DC voltage solutions)

- 0.25 kW - 7.5 kW

Undrive M700:

- 208 - 230 Vac | 380 - 460 Vac | 575 Vac | 690 Vac

- 0.75 kW - 2.8 MW

Unimotor HD:

- Winding voltage for inverter supply of 200 V and 400 V

- 60mm & 89mm: Max RPM is 6000

- 142mm & 190mm: Max RPM is 3000

- Torque range: from 0.64 Nm to 85 Nm

- 0.44kW to 13.8kW

Total Solution – Control Software Features:

Programable Limits:

- Speed

- Force

- Torque

- Position

Programmable Options:

- Press control

- Solenoid locking (failsafe)

- Bump-less (torque memory prior to locking)

- Spool winding logic

- High-Speed, High-Force programable logic

- Quality checks (pass/fail)

- Data logging

- Standard fieldbus interfaces

- Diagnostic tools

- Auto Control-Loop Tuning

Factory Support:

- Fully tested to the specifications

- Tuned control loops

- Documentation

- Remote technical support

- 7in Touchscreen

- PC Based (VBA)

Fieldbus Connectivity:

- CANopen

- Ethernet TCP/IP

- Ethernet IP

- EtherCAT

- Modbus TCP

- Modbus RTU

- Profinet

- Profibus

- Or Analog/Digital