The Kyntronics Advantage

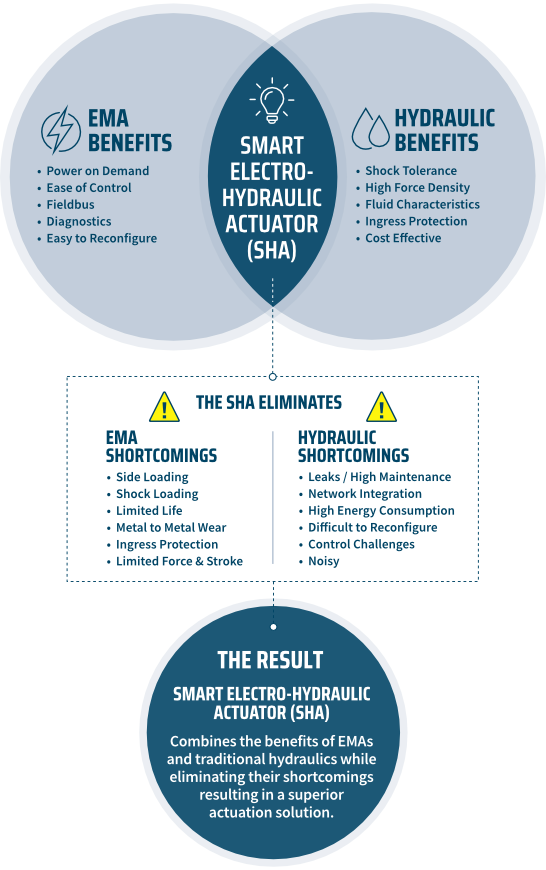

Historically there were Two Actuation Options: Electro-Mechanical Actuators (EMA) and Traditional Hydraulics.

But Now There is a Better Option

The Kyntronics SMART Electro-Hydraulic Actuator SHA, combines the Benefits of Both Electro-Mechanical Actuators (EMA) and Traditional Hydraulics while eliminating their shortcomings. Resulting in an actuation solution with superior functionality at a lower price point.

See Why the Kyntronics SHA Electro-Hydraulic Actuator is the Superior Solution over traditional hydraulics and electro-mechanical actuator solutions.

- SHA Product Design Elements

- Designed for Maximum Reliability and Minimal Maintenance

- Actuator Reliability Comparison: SHA vs. Ball Screw / Roller Screw Actuator

- Annual Operating Cost Comparison Kyntronics SMART Electro-Hydraulic Actuators (SHA) vs Traditional Hydraulic system (HPU)

Contact Us

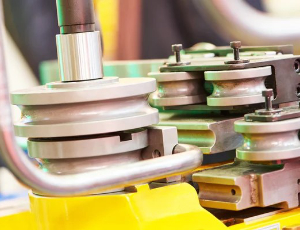

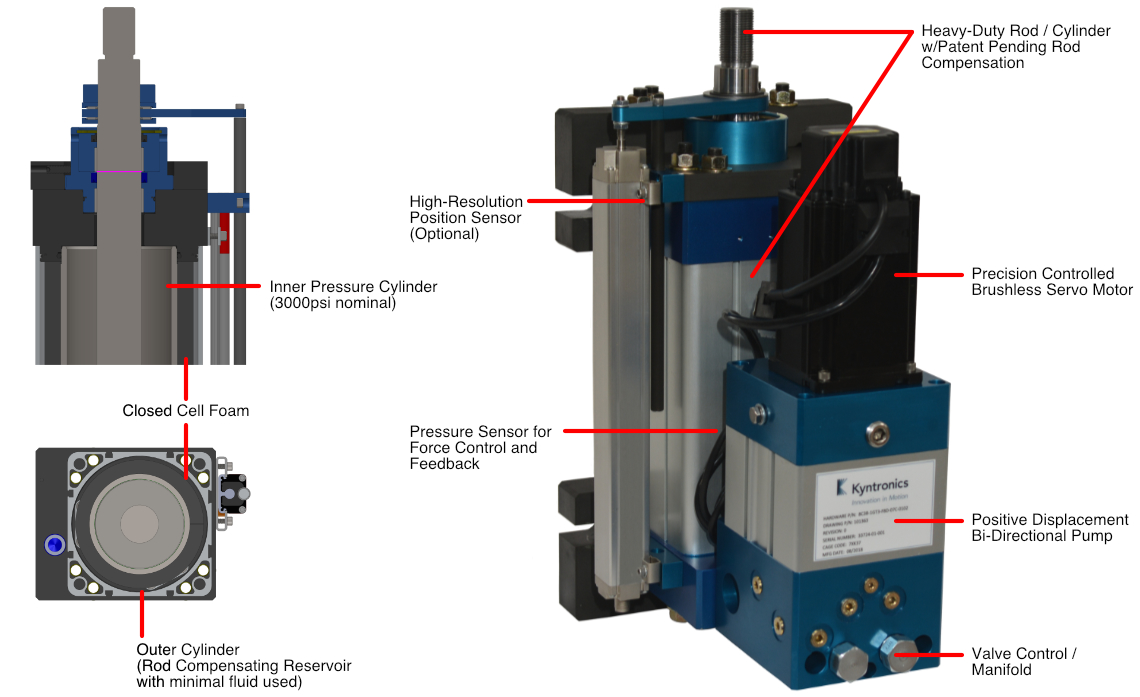

SHA Product Design Elements

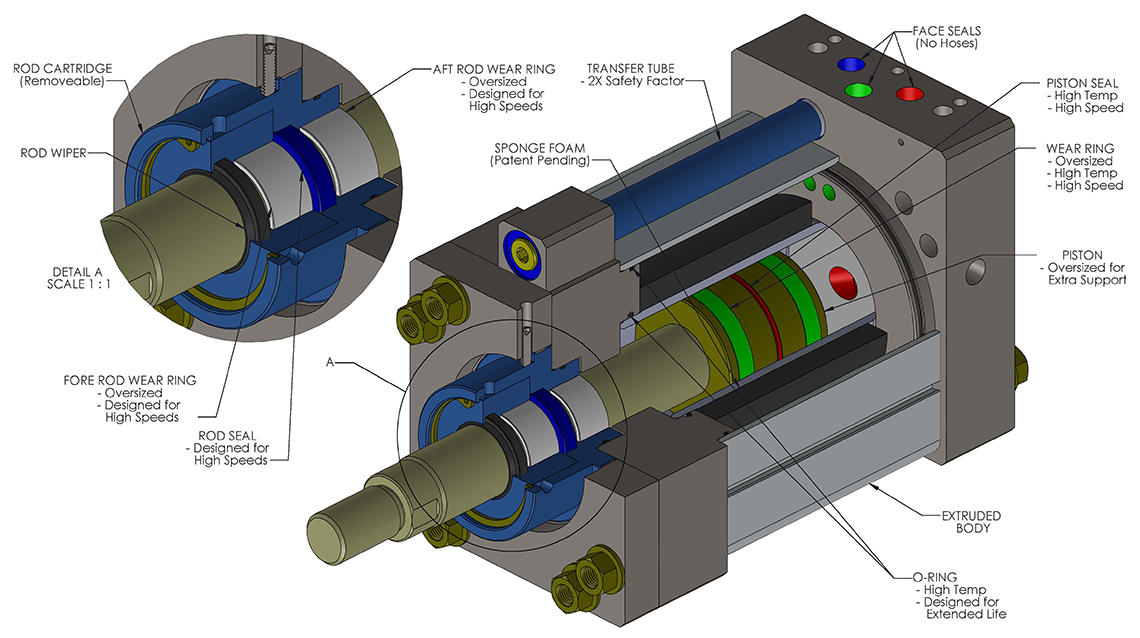

Designed For Maximum Reliability and Minimal Maintenance

Design Features Include:

- No metal-to-metal wear points

- Rod seal tested to over 50 million inches of travel without failure (load independent)

- Closed system eliminates contamination, moisture and air infiltration

- Oversize wear rings and bearings provide extra support during rod-extension

- Servo control eliminates pressure spikes

- Relief valves eliminate over pressure

- Temperature monitoring eliminates over-temperature conditions

- Minimal fluid; for example: estimated volume of fluid is 30 fluid ounces for a 2.0” bore X 3.0” stroke with a 1.0” rod diameter

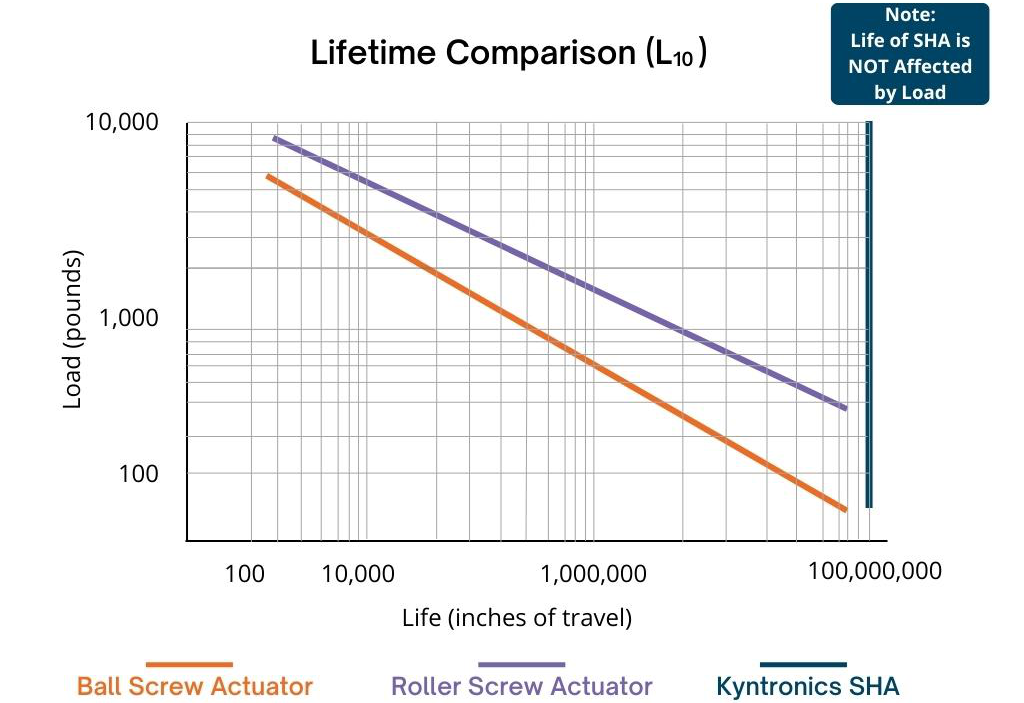

Actuator Reliability Comparison: SHA vs. Ball Screw / Roller Screw Actuator

- EMA Life is load dependent. Improving EMA life requires larger and more expensive size screws

- EMA Metal-to-Metal Wear further decreases reliability and requires regular lubrication

- EMAs are highly susceptible to damage from shock loads and side-loading

- SHA is rated at 50,000,000 inches of travel (before a simple rod seal change) regardless of load.

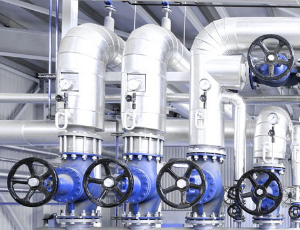

Annual Operating Cost Comparison

Kyntronics SMART Electro-Hydraulic Actuators (SHA) vs Traditional Hydraulic

Swipe to see the rest of the table

| Operating Cost Component | SHA | HPU | Assumptions / Cost Basis (April 2022) |

|---|---|---|---|

Environmental |

200 Gallon HPU Tank Hydraulic Fluid Index (HFI) = 4.1 SHA is sealed - no fluid replacement or disposal is required |

||

| Oil Replenishment Used Oil Disposal |

$0 $0 |

$33,600 $16,000 |

$42/gal X 800 gallons (4:1 HFI) $20/gal X 800 gallons (4:1 HFI) |

Energy |

SHA Uses Power on Demand 30 HP Hydraulic Power Unit that Runs Continuously SHA is 70% efficient (based on Kyntronics testing) HPU 22% is efficient (based on IFPE paper) |

||

| Energy Usage | $1,642 | $16,429 | Using $0.17 per KWh (rates vary from - $0.08 to $0.19 KWh) |

Floor Space Utilization / Maintenance Time |

SHA is All-In-One, no floor space required HPU requires space of 10'x10' = 100 Sq-Ft @ $20 per sq-ft |

||

| Floor Space Maintenance Time |

$0 $1,750 |

$2,000 $5,250 |

SHA @ 1 hr/week @ Labor $35/hr HPU @ 3 hrs/week @ Labor $35/hr |

Human Factor |

HPU oil leaks create hazardous conditions and safety risk SHA is totally sealed, no oil leak risk |

||

| Time off / Medical / Legal | $0 | $2,000 | Lost days + Medical costs + Legal costs |

Machine Downtime / Product Scrap |

|||

| 80% of unplanned machine downtime is caused by contaminated lubricants Product Spoilage |

$0 $0 |

$10,000 $10,000 |

SHA is totally sealed, no oil leak risk, minimal downtime risk. $10,000 $4k-$6k average downtime costs per incident. Assuming two downtime events. 1% scrap from product contamination due to leaky connections |

Annual Operating Costs |

$3,392 |

$95,279 |

An $91,887 Annual Savings Opportunity! |

References:

The basis for several of the assumptions used in the annual operating cost table originate from Fluid Power Industry published statistics and sources noted below: