AGV Lifting System

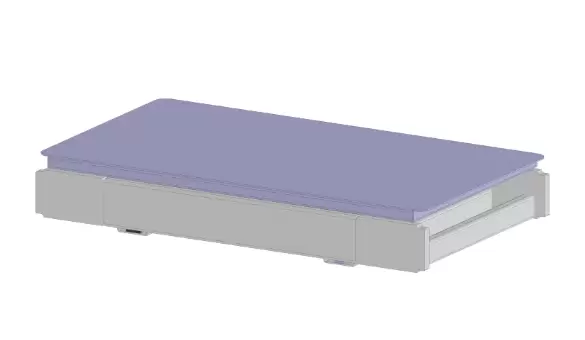

Application: Battery Powered Automated Guided Vehicles – Body / Chassis Marriage Lift

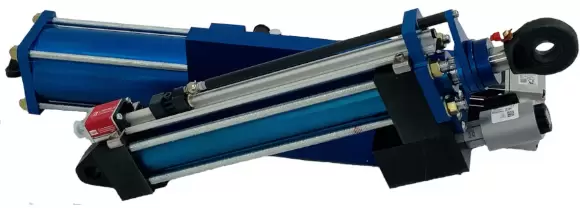

Product: E-Series SMART Electro-Hydraulic Actuators – DC Powered

Automotive Assembly Plant - AGV Body / Chassis Marriage Lift

Battery-powered Automated Guided Vehicles (AGVs) continue to be used in more applications. On AGV applications that require lifting and material positioning, Kyntronics has worked with several OEMs to address the unique challenges these applications entail.

Challenge:

An auto manufacturer had to re-tool the body / chassis marriage lift operation to implement AGVs vs. fixed conveyors used previously. The manufacturer had several key design objectives required for the AGV actuation system including:

- Must be highly energy efficient to maximize operational time before charging.

- Must operate from 48 VDC supplied by AGV battery power.

- Requires a total of 10,000 LBs of force yet must be very small to fit the limited envelope available in the AGV.

- The AGV platform required precise and programmable position control.

- A complete solution was required including actuators, cables, and drives.

These objectives presented some difficult challenges for the Manufacturing team. They immediately ruled out HPUs and hydraulic cylinders due to their large size and poor energy efficiency. Roller screw actuators were also considered but for the forces required, they would not fit the available space envelope, plus there were concerns about concentrated loads that would wear out the roller screws in a few months of production use.

Retracted Position

Retracted Position Extended Position

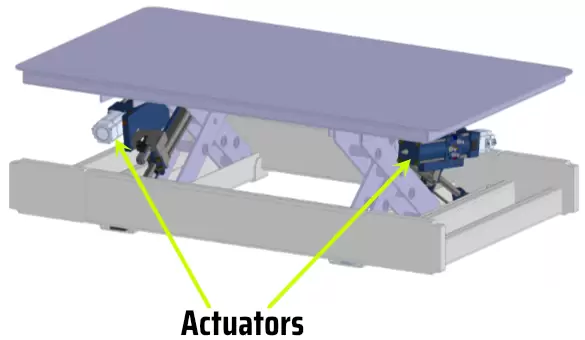

Extended Position

Solution:

The machine builder selected Kyntronics SMART Electro-Hydraulic Actuators (SHA) for the new AGV installation. Kyntronics worked closely with the machine builder to create a unique SHA packaging configuration that fit the challenging space envelope while providing the force required from the actuator operating at 48 VDC. Additionally, Kyntronics provided a 2-axis VeKtor control using 48 VDC drives that precisely synchronized the fore and aft actuators. The system was provided turnkey with actuators, cables and drive/controller simplifying installation and integration.

Kyntronics SHA with innovative packaging; produces 5,000 LBs force @ 48 VDC

Kyntronics SHA with innovative packaging; produces 5,000 LBs force @ 48 VDC Kyntronics Body / Chassis AGV Actuation System: Two – 48VDC SHA actuators with two-axis VeKtor Controller

Kyntronics Body / Chassis AGV Actuation System: Two – 48VDC SHA actuators with two-axis VeKtor Controller