Five Things You Should Know About Hybrid Electro-Hydraulic Actuators

Overview

Kyntronics hybrid actuators combine features used in electro-mechanical actuators with features used in hydraulic cylinder actuators. The result is an innovative actuation solution that provides unique benefits to machine builders and end users.

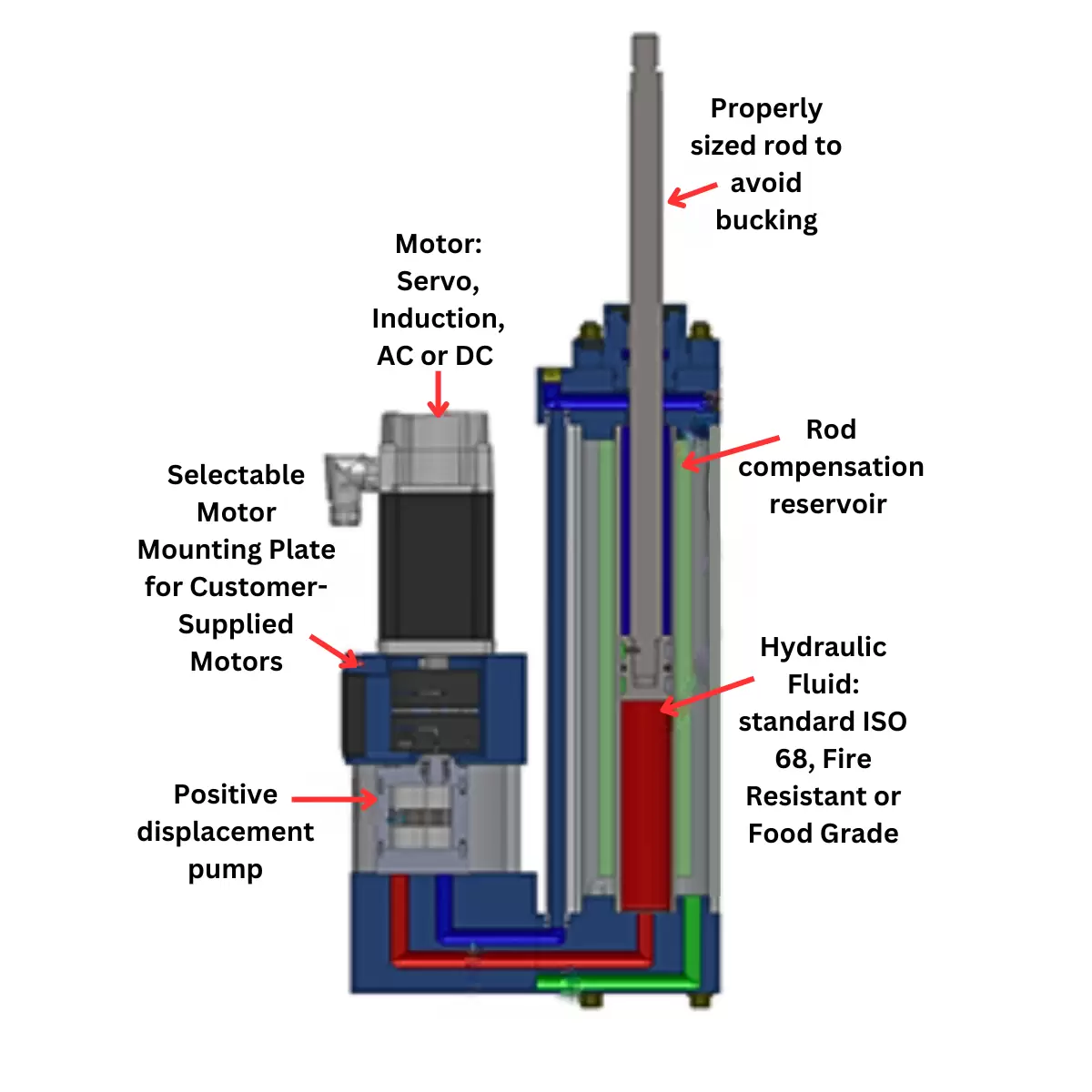

The hybrid electro-hydraulic actuator aka (SHA) is electrically powered. It is a linear actuator with a totally sealed design incorporating an integral cylinder driven by an attached motor and pump operating on a closed circuit using a small volume of fluid that is not exposed to the environment. The fluid does not require replenishment or replacement (see figure 1).

Figure 1: How our Actuators work

Figure 1: How our Actuators work

Five Things You Should Know About Hybrid Electro-Hydraulic Actuators

1. The Hybrid actuator incorporates a sealed design that uses a minimal amount of fluid. An innovative rod compensation reservoir eliminates the need for an external tank or accumulator and the totally sealed design with no hoses minimizes risk of leaks and eliminates the need for fluid and filter changes. Minimal fluid is required. For example, an actuator that produces 10,000 Lbs. of force with an 8” stroke only requires 14 oz of fluid.

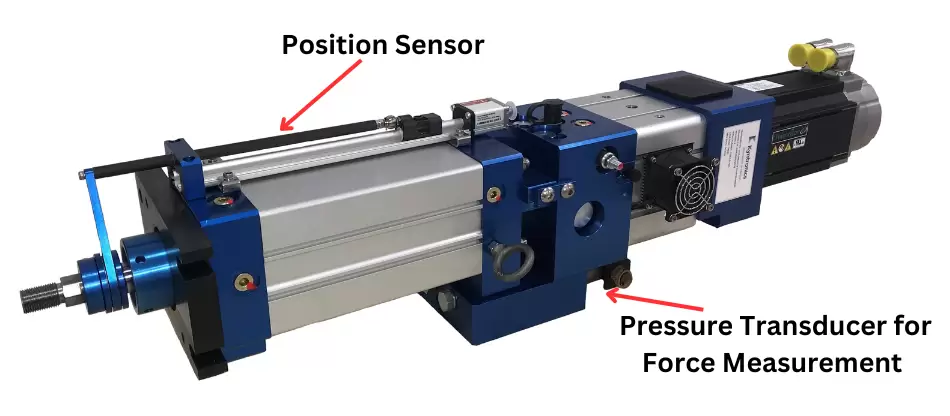

2. Hybrid actuators provide precise control of position, force, speed and dwell. These actuators are often referred to as “servo actuators” or “servo hydraulic actuators”. They incorporate feedback sensors for position and pressure (see figure 2) that are connected to the drive/control system for precise closed-loop actuator control.

Figure 2: Precise control of position, force, speed and dwell

Figure 2: Precise control of position, force, speed and dwell

3. The Hybrid actuator has an integral cylinder that absorbs shock loads and eliminates metal-to-metal wear. This design approach results in a robust actuator that can be confidently used in industrial applications and does not require regular lubrication maintenance.

Metal-to-Metal wear with the many components in Roller Screw EMAs result in premature wear and failure risk from shock and side loads

Metal-to-Metal wear with the many components in Roller Screw EMAs result in premature wear and failure risk from shock and side loads

4. Hybrid actuators are available in many configurations with standard stroke lengths up to 120” (3,048mm). The unique design allows many flexible arrangements of actuator modules with very cost-effective long stroke options.

5. Hybrid actuators use power-on-demand and are highly efficient to reduce energy costs. The sealed design eliminates hoses, valves, and connections that result in energy losses. Kyntronics customers report up to 10X in energy savings vs. traditional hydraulic cylinder actuator / HPU systems.

Kyntronics hybrid electro-hydraulic actuators are available in a wide range of sizes:

- Force Ratings: from <100 lbs. (0.4 kN) to 150,000 lbs. (667 kN)

- Speed: up to 34.5 in/s (877 mm/s)

- Stroke Length: any increment up to 120 in. (3,048 mm)

- Input Power: 24 – 80 VDC or 120 – 480 VAC

Kyntronics hybrid electro-hydraulic actuator w/attached Control. 100 lbs. rated force.

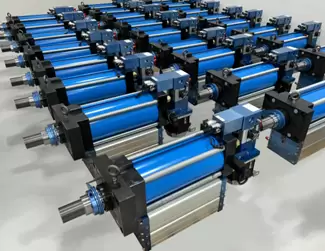

Kyntronics hybrid electro-hydraulic actuator w/attached Control. 100 lbs. rated force. Kyntronics hybrid electro-hydraulic actuators. 150,000 lbs. rated force

Kyntronics hybrid electro-hydraulic actuators. 150,000 lbs. rated force

Kyntronics hybrid actuators combine the strengths of multiple actuator technologies to provide better performance, efficiency, and versatility compared with alternative actuators. Using this approach, hybrid actuators can optimize factors including speed, precision, power, and energy consumption, making them valuable in applications where these qualities are important—such as automation, robotics and special machines.

Learn more about the Kyntronics Hybrid electro-hydraulic actuator difference.

Find Solutions to Your Actuation Problems

Our engineers work closely with each customer to select the optimal actuation solution to address your unique application requirements. If you’d like to learn more about the actuation solutions Kyntronics has to offer, contact a member of our team today! We look forward to solving your actuation challenges.