Electric Cylinder Configured to Application Requirements

One of the major advantages of Kyntronics actuators is how the SMART actuator technology can be configured to fit highly specific and unique needs for our customers.

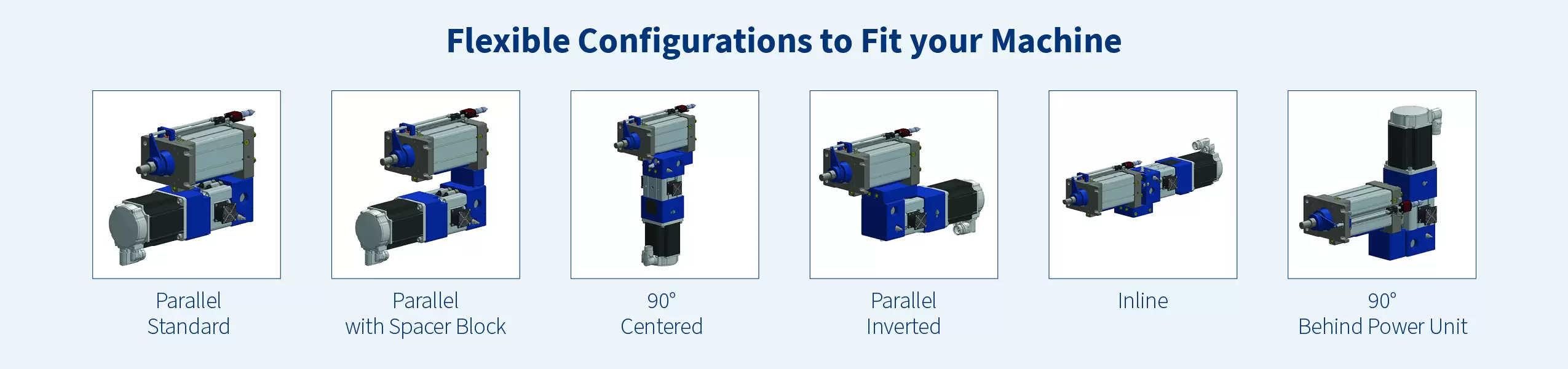

Traditional screw-type electric cylinders are available in a limited number of configurations e.g. inline or parallel styles, due to the power transmission methods utilized such as gearboxes, belts or direct drive. This restricts the options available to fit limited space envelopes.

Kyntronics actuators utilize a fluid path to transmit power from the internal pump to the cylinder which when coupled with our standard modular building blocks, allow for a significant number of configurations including some popular variations shown in figure 1.

How multiple configuration options provide flexibility

Kyntronics SMART Electro-hydraulic Actuators (SHA) are used in a wide range of industries and applications. With available forces up to 150,000 lbs. and stroke lengths to 120 in., the SHA is applied successfully in all but extremely high force applications.

Today’s equipment builders and end users require higher performance from their machine investments. Key factors include: energy efficiency, precise process control, data for quality evaluation / predictive maintenance and IoT connectivity. Actuator control functionality is critical to achieving these benefits.

Kyntronics offers multiple actuator control options including the “Total Solution”; a complete package including actuator, motor, drive and control that provides extensive software capabilities. In addition, the SHA is available in an “Actuator Only” option for connection to the motor/drive/control of your choice.

Flexible mounting options for Kyntronics actuators

The SHA has an extensive variety of mounting options for both the rod end and actuator. Rod ends include spherical ball joint, standard threaded male or female, clevis, rod eye, and Parker style. Actuator mounts include Clevis, Rod Eye Bracket, Front or Rear Flange plates, end or side feet, trunnion.

Factory Support makes the Difference

Regardless of how simple or complex your application is, Kyntronics works with you from start to finish:

- Sizing the actuator, motor and drive

- Approval models and electrical schematics

- Tuning control loops

- Full factory system test of all components

- Remote start-up support

We work closely with each of our customers to ensure that we fully understand the particular application before configuring an actuator that will meet the requirements.

Curious if Kyntronics actuators have been applied in your industry or a similar application? It is highly likely that it has.

View our applications library here