Electric Servo Actuators – Comparing Types of Technologies

Comparing Types of Actuator Technologies - Servo Electro-Hydraulic (SHA) vs. Electro-Mechanical (EMA) vs. Hydraulic (HPU with Cylinder)

Not sure which type of Actuator Technologies is right for your project?

View a comparison among Servo Electro-Hydraulic (SHA), Electro-Mechanical (EMA) and Hydraulic (HPU with Cylinder) technologies in 5 key categories:

- Reliability / Maintenance

- Precision Control

- Space / Ergonomics / Environment

- Economics / Cost of Ownership

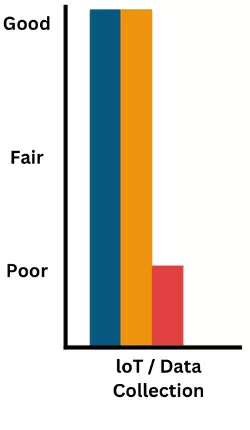

- Data Collection

You can get more technical information about our SMART Electro Hydraulic Actuators and technical details comparing actuator types with our free Actuator Comparison Guide.

Servo Electro-Hydraulic (SHA) vs.Electro-Mechanical (EMA) vs.Hydraulic (HPU with Cylinder)

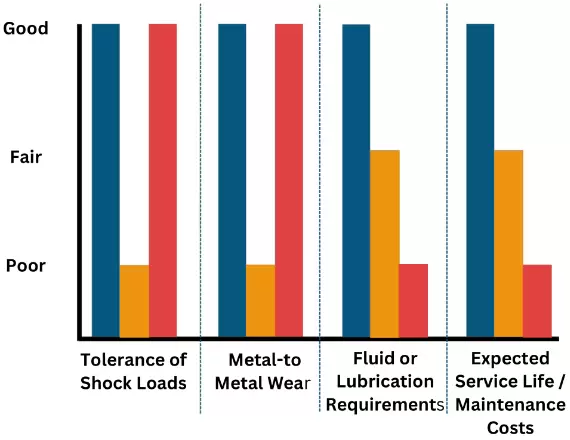

Reliability / Maintenance

- EMAs are damaged by shock loads and wear from metal-to-metal contact. Must be oversized to extend life.

- EMAs require frequent lubrication to extend service life.

- SHA requires no PM other than a rod seal change (after years of use).

- Hydraulics require regular replacement of oil, filters, hoses and other components.

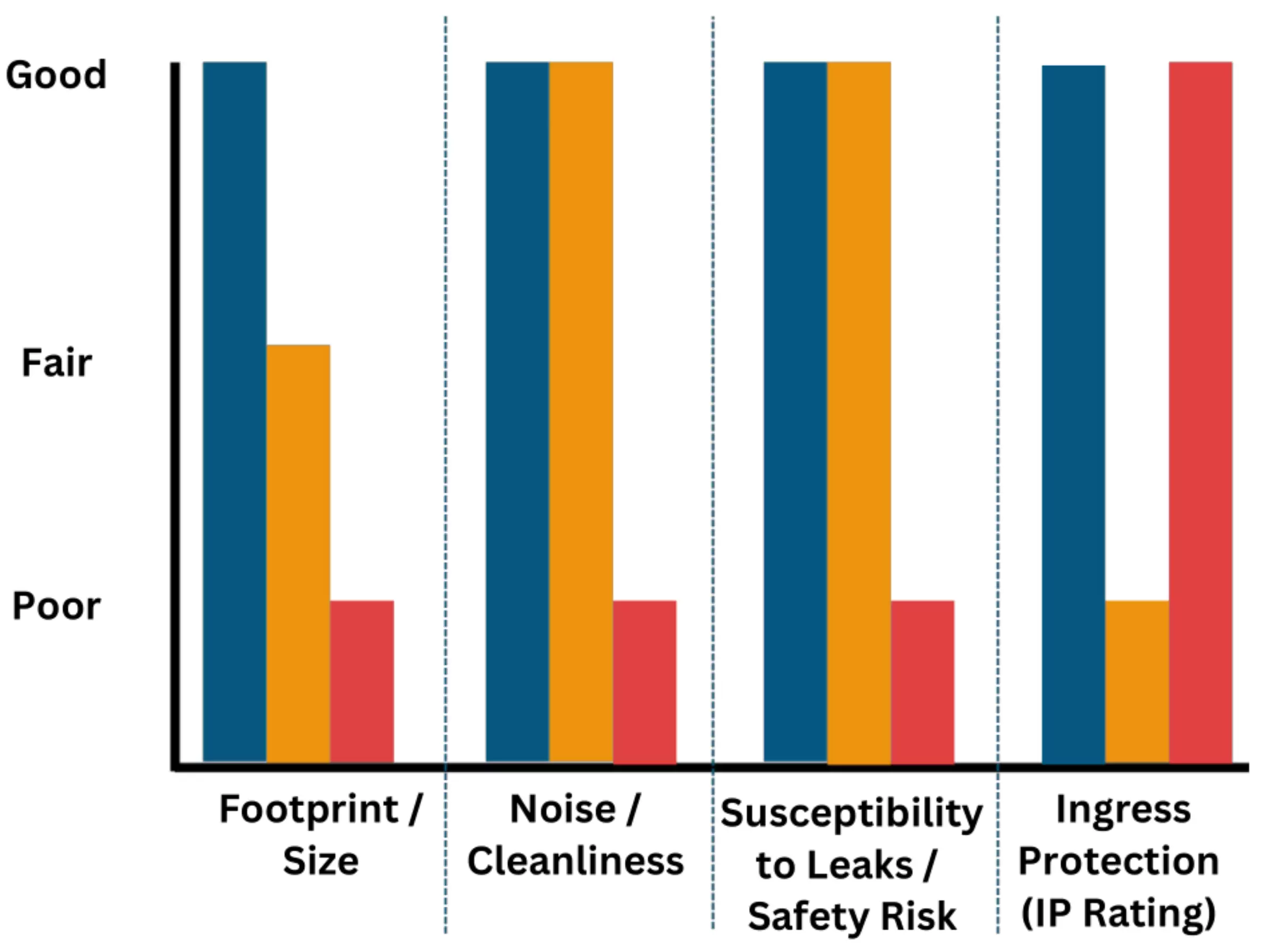

Space / Ergonomics / Environment

- SHA has Force density of a hydraulic cylinder without the HPU. SHA contains minimal fluid.

- EMA Force-density is lower than a Hydraulic Cylinder.

- Hydraulics frequently leak, are dirty and create noisy and unsafe conditions.

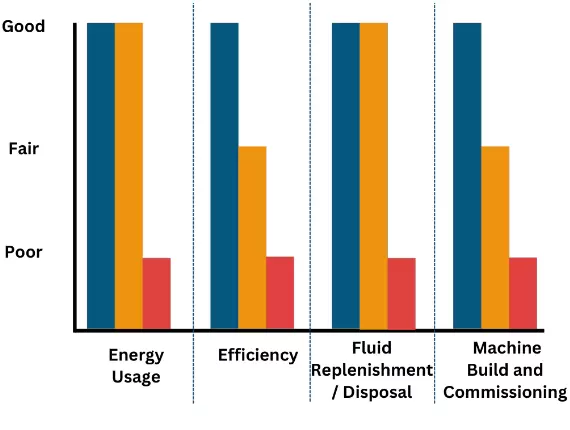

Economics / Cost of Ownership

- Power-on-Demand saves energy.

- Metal-to-Metal Friction reduces efficiency.

- Hydraulics run continuously, are very inefficient, and require regular fluid changes. • SHA is all-in-one while Hydraulics have many components.

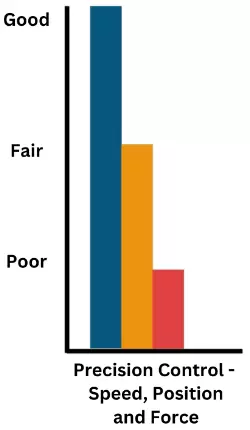

Precision Control

- EMAs require expensive load cells for force measurement.

- SHA is an electric servo actuator.

Data Collection

- Hydraulics require expensive instrumentation for IoT.