Actuators are often used in Clamping and Holding applications to apply force to materials or components. Some examples include:

- Injection and blow molding

- Tube and wire bending

- Metal forming

- Pressing of various materials

- Assembly machines

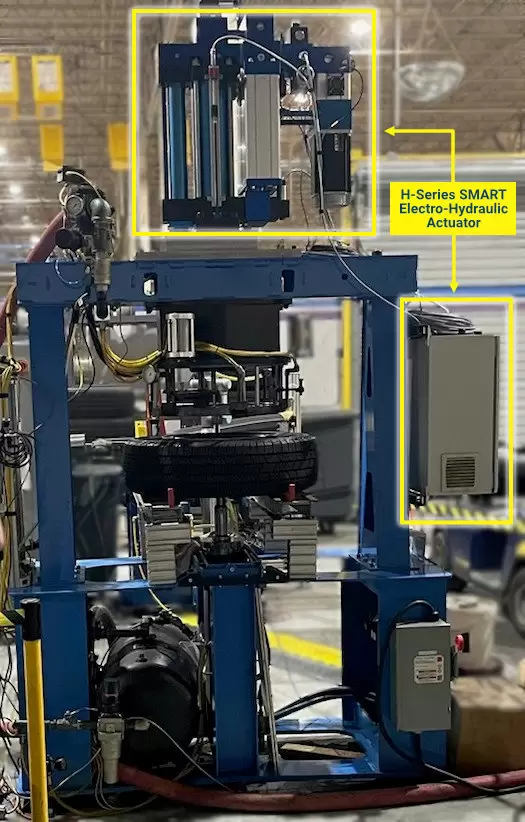

- Test equipment

Clamping actuators have unique requirements for successful operation including:

- Accurate and programmable position control

- Accurate and programmable applied force control

- Fast extend and retract speeds to optimize cycle times

- High force actuation

- Programmable acceleration/deceleration profiles that avoid damaging material and tooling

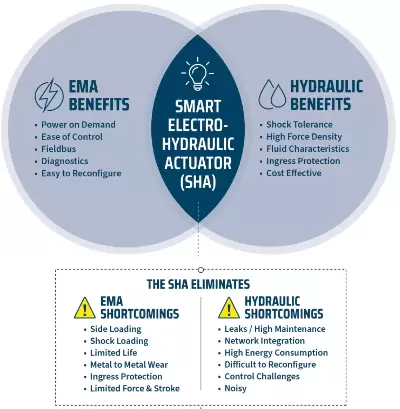

Traditional hydraulic power units with hydraulic cylinders and screw-type electro-mechanical actuators are options for clamping applications, however, the Kyntronics SMART Electro-Hydraulic Linear Actuator (SHA) is an excellent electric servo actuator alternative that out-performs these other actuation technologies.

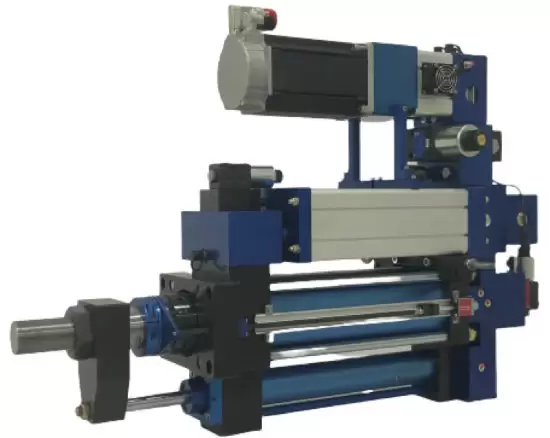

Kyntronics SMART Electro-Hydraulic Actuator (SHA)

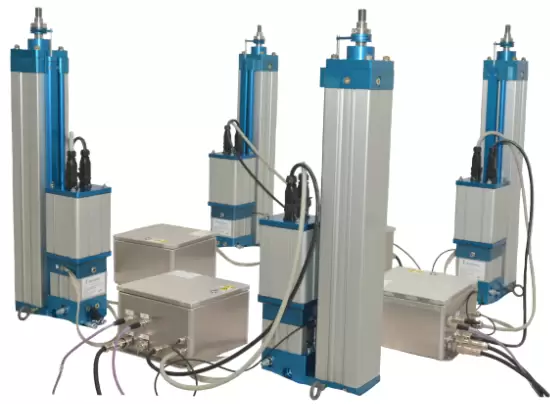

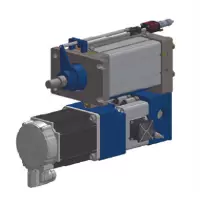

The SHA is an all-electric, all-in-one, totally sealed, self- contained linear actuator consisting of a cylinder, pump, manifold and servo motor with optional drive/control system.

There are no hoses or leak points on the SHA vs. a traditional hydraulic cylinder / HPU system and the SHA contains minimal fluid (generally measured in ounces).

Unlike other actuators, the SHA is available in many flexible configurations to fit your machine

Parallel Standard

Parallel Standard Parallel with Spacer Block

Parallel with Spacer Block 90° Centered

90° Centered Parallel Inverted

Parallel Inverted Inline

Inline 90° Behind Power Unit

90° Behind Power Unit

Despite being a robust high force solution, traditional hydraulic cylinders connected to Hydraulic Power Units (HPUs) have a number of shortcomings to consider when evaluating this actuation option:

- Inevitable leaks causing safety and environmental issues

- High energy consumption

- High costs for hydraulic fluid replenishment and disposal

- High maintenance requirements and costs

- They are expensive for higher force (>5,000 Lbs) applications

- Susceptible to premature failure from shock loads and metal-to-metal wear due to concentrated loading.

- Require regular maintenance and lubrication to prolong screw life

- Have limited stroke length.

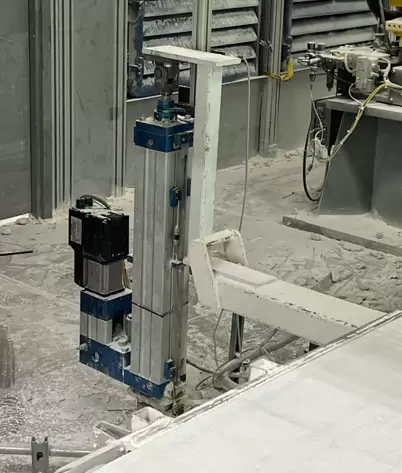

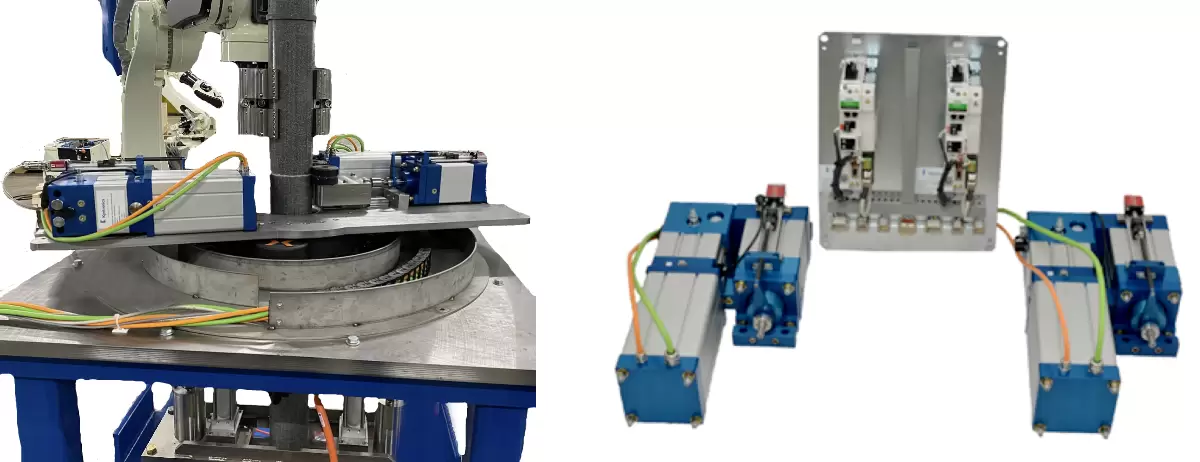

SMART Electro-Hydraulic Linear Actuators are Used in many Clamping and Holding applications

Metal Fabrication – Clamping material for bending and hole punching – Appliance Industry

Metal Fabrication – Clamping material for bending and hole punching – Appliance Industry  Assembly - Clamping components for hydroforming and bending – Automotive Industry

Assembly - Clamping components for hydroforming and bending – Automotive Industry  Tube Bending - Clamping material for forming and bending – Automotive Industry

Tube Bending - Clamping material for forming and bending – Automotive Industry  Testing – Clamping components for pressure testing of gas meters - Energy Industry

Testing – Clamping components for pressure testing of gas meters - Energy Industry  Packaging – Long-Stroke actuators for bundling steel fabrications – Construction Industry

Packaging – Long-Stroke actuators for bundling steel fabrications – Construction Industry  Servo Power Units w/Customer Cylinder – Clamping metallurgical wear part components for grinding and polishing - Agriculture Industry

Servo Power Units w/Customer Cylinder – Clamping metallurgical wear part components for grinding and polishing - Agriculture Industry