Solving Press Problems with High Performance Linear Servo Electro Hydraulic Actuators

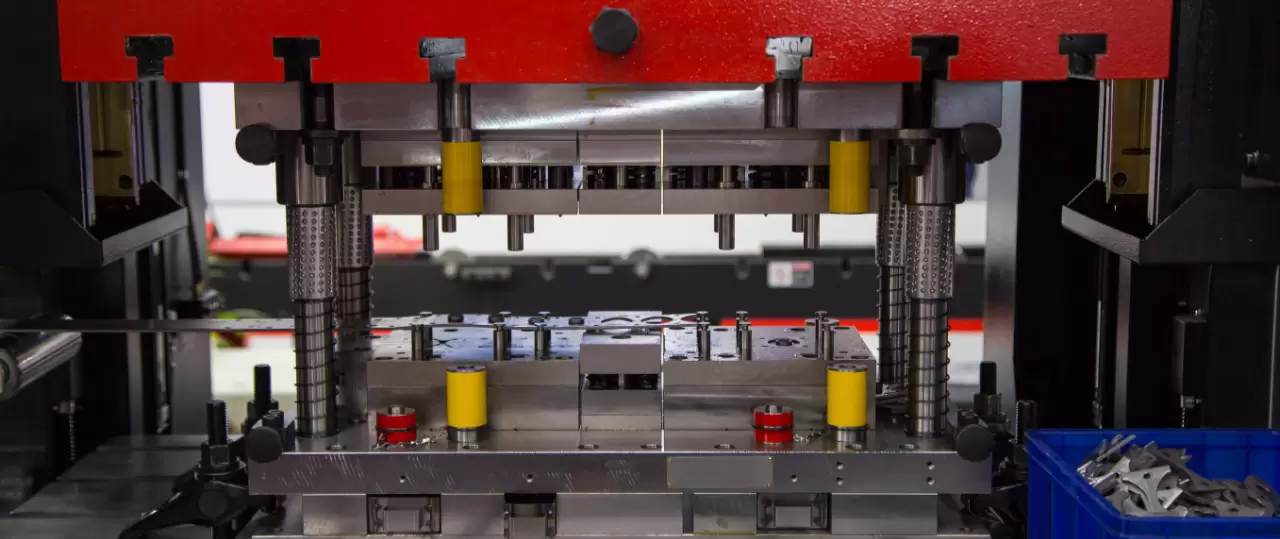

Kyntronics actuation systems are successfully applied in virtually every application and industry. We have helped many of our customers solve actuation problems and improve their equipment by providing them with configured actuators from our linear actuator product family. One of the many applications that our actuators are used on is presses.

Typical Press Applications

There are many types of industrial presses in use today. Some common press applications include:

- Sheet metal stamping

- Metal Punching

- Metal forming

- Assembly presses

- Bearing presses

- Riveting and fastening

- Laminating

- Plastic molding

- Composite molding

- Powdered material forming

- Thermal forming

- Material testing

Press Problems - Challenges of Press Technology / Increasing Customer Expectations

As customer requirements for press equipment increase, requiring more automation, more precision control, lower maintenance, maximum reliability and data collection, the actuation systems used on presses will need to meet these expectations. In addition to increased expectations, there are a number of press problems equipment builders are facing.

Presses typically require significant force to perform their intended function which usually means incorporating hydraulic actuators powered by a hydraulic power unit (HPU). However, hydraulic actuators come with several challenges for the press manufacturer and press user. The HPUs used must be constantly powered whether doing work or not. This creates significant energy waste and inefficiency. In addition, hydraulic systems will experience fluid leaks that create safety risk, unplanned downtime, product spoilage and high maintenance costs for fluid replenishment and disposal. While hydraulics are very robust and power-dense, they don’t provide precise motion control without additional expensive, complex components compared to other actuators.

Servo-driven roller screw and ball screw electric actuators provide an alternative to hydraulic actuators particularly when lower forces are required. They can provide the precision needed along with power on demand for energy savings but are fragile and far more susceptible to damage from shock loads and running into end stops. Their use of gears, nuts, screws and other mechanical components creates metal-to-metal wear that reduces reliability and creates higher risk of unplanned downtime. They also cannot match the power and durability of a hydraulic actuation system.

Kyntronics’ Solutions for Press Problems – A Few Short Case Studies

To address the challenges of actuation requirements for presses and other applications, Kyntronics developed the all-electric SMART Electro hydraulic Linear Actuation system (SHA).

The SHA combines the benefits of both screw-type and hydraulic actuators, while eliminating their shortcomings. The SHA is available with force ratings of 100 – 150,000 lbs. of force and multiple SHAs can be synchronized together to achieve even higher force ratings. In the world of press applications, we have been able to solve many press actuation problems for our customers.

Metal Forming Line for Appliances

A manufacturer of appliances needed an actuation alternative to hydraulics for a new automated metal forming production line. They had several issues with leaks, high energy costs and extensive maintenance on their previous line. Their goal was to improve process quality, lower energy costs and reduce maintenance while having the confidence the new actuators were robust enough to handle the rigors of metal bending, hole punching and coining in medium gauge metal.

For this application, Kyntronics provided several all-electric SMART electro hydraulic linear actuators with servo control. These actuators improved process control while helping save the manufacturer thousands of dollars in energy costs and reduced maintenance. In addition, the new line was much quieter due to the elimination of the noisy HPUs used on the previous line.

Bearing Assembly Press - Tier 1 Auto Supplier

A machine builder of various types of seal, bearing, and assembly presses came to Kyntronics with an application for a Tier 1 automotive customer who wanted to eliminate hydraulics from their production line while improving the accuracy of force and position control of their bearing assembly machines. The builder’s customer also required quality process verification of each press cycle and data capture during their pressing process. A screw-type actuator couldn’t handle the shock loading inherent in the application and the customer was concerned about reliability risk.

Kyntronics provided an all-electric SMART electro hydraulic linear actuation system with servo control that performed the press cycle using both position and force control with pass/fail determination along with providing the customer with cycle data to monitor their process quality. This system, like our other SHA products, featured a totally sealed actuator with servo motor, drive and control meeting the needs of both the press builder and their automotive customer.

Previous Solution with HPU

Previous Solution with HPU Kyntronics Solution

Kyntronics Solution

Whiskey Barrel Press Retrofit

A wine and whiskey barrel manufacturer was using roller screw actuators on their barrel assembly press machine that were failing almost daily due to shock loading that caused extensive unplanned downtime and high maintenance costs. A new solution was required that would be more reliable but could not use hydraulics due to concerns about leaks that would cause product spoilage. The new solution needed to be retrofit on the existing barrel press using the same space envelope.

Kyntronics provided the machine retrofitter with an all-electric SMART electro hydraulic linear actuation system (SHA) with servo control that performed the press cycle using both position and force parameters. The SHA that was installed used a minimal amount of food grade oil due to it’s totally sealed design. The SHA remains operational after several years without a single failure due to it’s ability to tolerate shock loads.

Find Solutions to Your Pressing Problems with Kyntronics!

At Kyntronics, our goal is to provide you with a linear actuator that actually works–one that can solve the problems inherent with press equipment and eliminate the need for bulky, leaky hydraulic systems. Check out all of our SMART products and request a quote today to get in touch with us on how we can assist you with your pressing problems!